Plastic pouch roll require batch printing and price printing before material filling in pouch,pouch roll has to be Treaterd before printing for better adhesion of ink , corona treatment alters the surface of the film and increases Dynes value. More receptive of inks better bonding, long lasting Printing.

Eltech Corona Treater system creates powerful bonding for printing, painting, coating,laminating and adhesion applications. Our technology is uniquely designed to treat 2-dimensional films, as well as many other applications requiring Improved surface energy and long-lasting activation.

Corona discharge treatment at atmospheric pressure for improving adhesion of various polymer substrates is now standard practice.

Our corona Treater machines give efficient prompt surface improvement for printing on all types of laminates like, Foil, Paper, LDPE, HDPE, PVC, etc.

The Batch Coding application for Winder Re-winder Machine is coupled beautifully & synchronized well with our eltech's corona Treater machine.

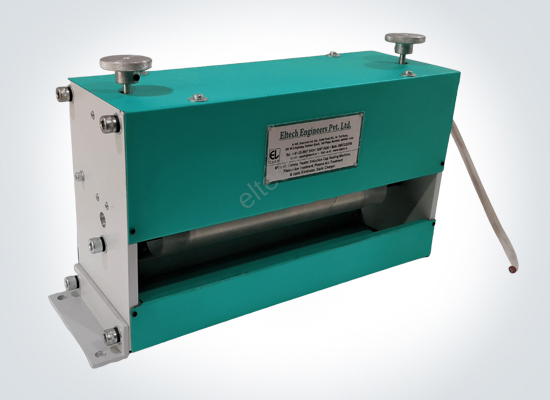

Corona Treater for Batch Printing Machine

High Frequency Corona Panel

H.V Transformer

Batch Printing Application :

- Price of the products etc.

- Printing of Mfg. Date.

- Batch No.

- Expiry Date

- Sr. No. etc

Features of Corona Treater for Batch Printing Machine :

- Aluminium Split box type station assembly for light weight and low corrosion.

- Advanced IGBT Technology.

- In order to protect the Treater rolls, a zero speed cut-off system automatically shuts down the power supply when the web achieves low line speeds.

- Pnuematic operated treatment station.

- Ozone extraction system efficiently removes ozone and to cool the electrodes. This reduces warping of electrode and provides more consistent.

- Easy to install.

- Cost efficient treatment process.

- Customized Design.

- Easy to maintain.

- Easy to Operate Push Buttons for Start/Stop

- Air gap adjustment: two external adjustment screws at both ends of the electrodes.

- Easy view windows allow clear unobstructed view of corona discharge.

- Compact simple contruction

- Ultra high frequency using latest IGBT technology

- Soft start

- Forced cooled convertor for longer life

- Maximum Operator safety

- Thermal trip for heatsink

- Overload Trip

- Under voltage / Over voltage

- MCB protection

- Single Phasing

- Ozone extraction overload trip

- Audio / visual alarm

- Door open